When planning to invest in a rock wool production line, one of the first questions investors ask is:

“How much does a rock wool production line cost?”

However, the real question should be:

What are you actually paying for, and which factors determine the final investment?

This article explains the key cost components, technical choices, and common mistakes to help investors make informed decisions.

Production capacity is the most important factor affecting total investment.

A typical rock wool production line is designed based on:

Tons per year (e.g. 10,000 – 50,000 tons)

Product type (boards, slabs, rolls)

Product width and thickness range

Higher capacity requires:

Larger melting furnace

Stronger fiberizing and forming systems

Higher automation level

Capacity decisions should be based on market demand, not just maximum output.

The melting furnace significantly influences both initial investment and long-term operating cost.

Lower electricity consumption

Suitable for large-scale continuous production

Requires stable coke and raw material supply

Cleaner operation

Easier temperature control

Higher electricity cost

Choosing the wrong furnace type can lead to long-term energy inefficiency and higher operating expenses.

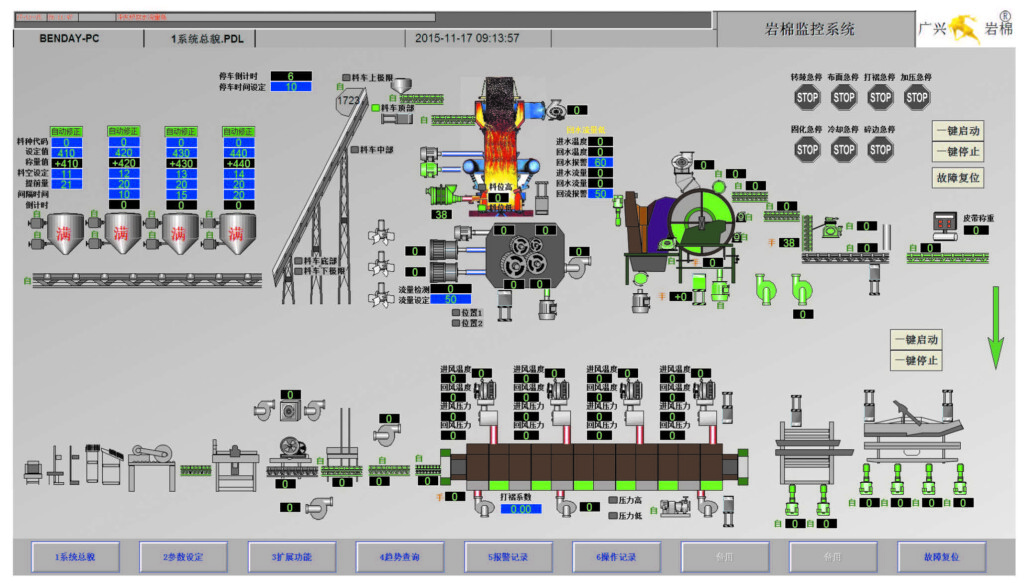

Automation directly affects:

Labor requirements

Product consistency

Production stability

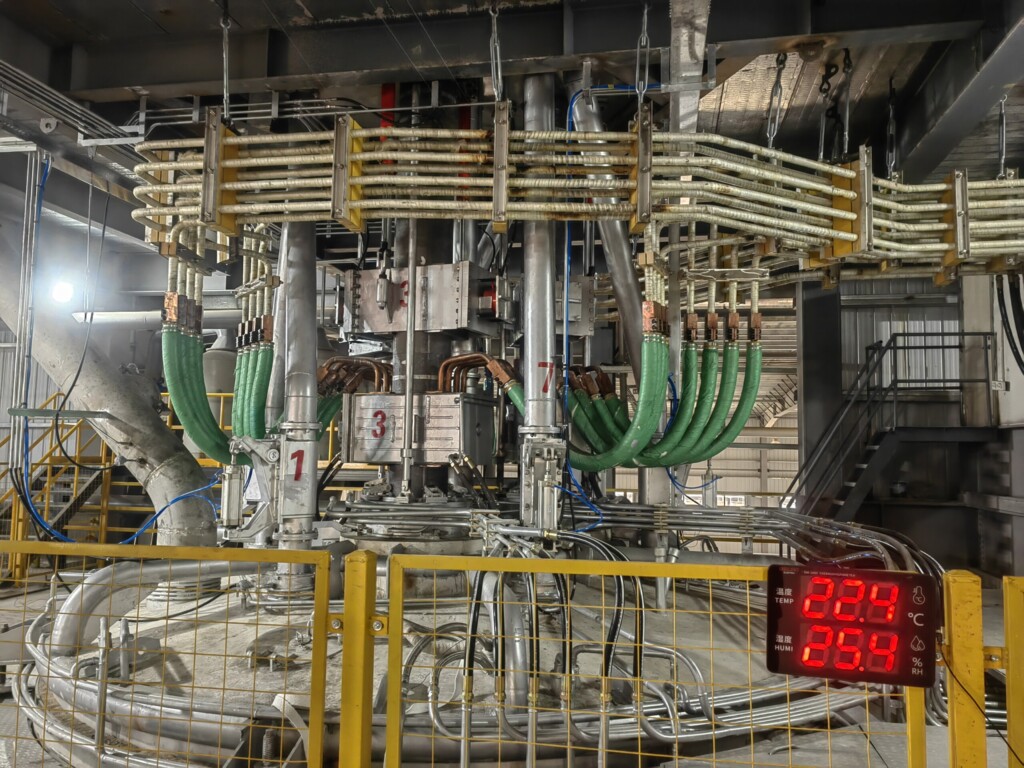

A modern rock wool production line integrates:

Centralized PLC control

Although higher automation increases initial cost, it significantly reduces labor dependency and operational risks over time.

Many investors focus only on the main production equipment but underestimate the cost of auxiliary systems, such as:

Dust collection and environmental protection

Cooling and curing systems

Packing and palletizing solutions

Electrical cabinets and control rooms

These systems are essential for stable, compliant, and long-term operation.

A rock wool production line is not a “plug-and-play” machine.

Total investment should include:

On-site installation supervision

Commissioning and parameter tuning

Operator training and maintenance guidance

Professional installation and commissioning reduce downtime and prevent costly trial-and-error production.

While exact prices vary, a complete rock wool production line investment typically depends on:

Capacity and layout

Furnace type

Automation level

Local energy and labor costs

Rather than focusing on a single price figure, investors should evaluate total cost of ownership over the production lifecycle.

Some common mistakes include:

Selecting capacity without market research

Underestimating energy and maintenance costs

Choosing equipment without technical support

Ignoring long-term spare parts availability

A successful project balances technical reliability, operating cost, and market positioning.

Investing in a rock wool production line is a long-term industrial decision.

Understanding the real cost structure helps investors avoid hidden expenses and ensures stable production performance.

Choosing an experienced supplier with proven project references and turnkey capabilities is often more important than pursuing the lowest initial price.

Hebei Guangxing Machinery Technology Co., Ltd (Guangxing), established in 1987, is one of the leading Rock Wool Production Line Supplier China and manufacturers of EPS, PU/Phenolic/Rock/Glass wool insulation panel production equipment. Guangxing enjoys a strong reputation both domestically and internationally and holds CE and ISO 9001:2008 certifications, with over 20 patents.

Copyright © 2025 Hebei Guangxing Machinery Co., Ltd. All Rights Reserved.